Thread and Profile Rolling Machines

Engineering innovations and experience led to advantages in thread manufacturing technology using cold rolling. Today there are useful processes and machines for nearly every rotation-symmetric profile. The Profiroll Thread Rolling Machines are outstanding in terms of workpiece quality requirement, possibility of connection to an automated handling system and Output.

Global characteristics of all Profiroll machines are:

- a statically and dynamically very stiff iron cast C-frame

- best accessibility to open work area for insertion and extraction of parts

- best accessibility during changeover

- Rolling force from 50kN to 1000kN

- Infeed and through-feed rolling

- a drive and control system created for operator needs

The Reliable

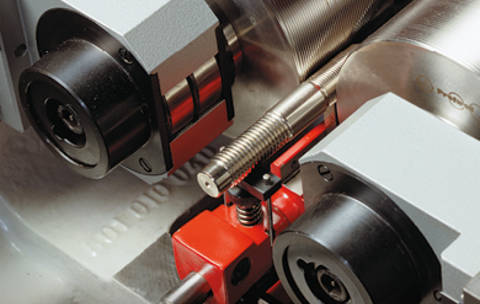

The Reliables are high flexible One-Slide Machines for Thread rolling and Profile rolling. This thread rolling machine type features rugged design, easily operated equipment and mechanisms. Thousands times sold and Reliable.

The Economical

The Economical One- and Two-Slide Thread Rolling machines and Profile Rolling machines for connection into serial production and unrestricted automation. The CNC-functions of this machine can be used for process control. Economical - because lowest rolling times in connection with ability to be automated.

The Innovative

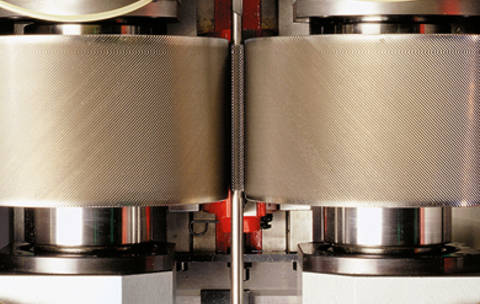

The Innovative are 2-Slide Thread Rolling Machines for high quality demands. The precision drives and guideways togehter with a Profiroll CNC based on Siemens 840D allow rolling of challenging external Profiles and especially parts with low wall thickness.

Fastener Machinery

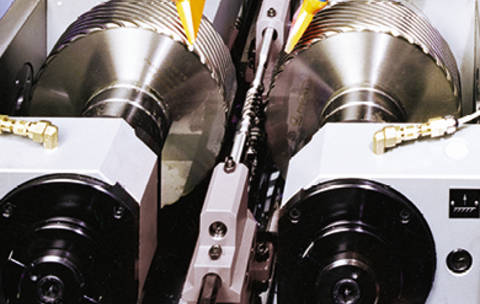

Fast. Faster. Fastener - Profiroll Fastener machinery for Circular-Segment-Dies with an output rate up to 1.500 pcs/min. realize your manufacturing target in economical production of threads.

3-Rolls Thread Rolling Machines

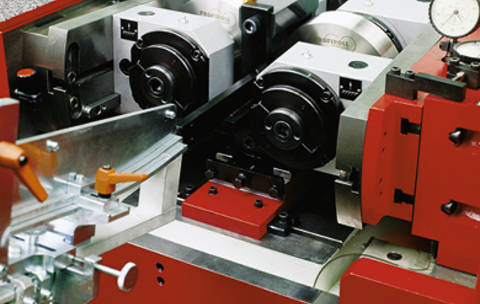

The 3-Rolls Thread Rolling machines, developed for rolling of hollow parts, satisfy with a high rolling quality resulting from centered positioning of parts and symmetric 3-side load due to usage of 3 Rolling Dies.