The Innovative - The next Generation

For highest profile quality

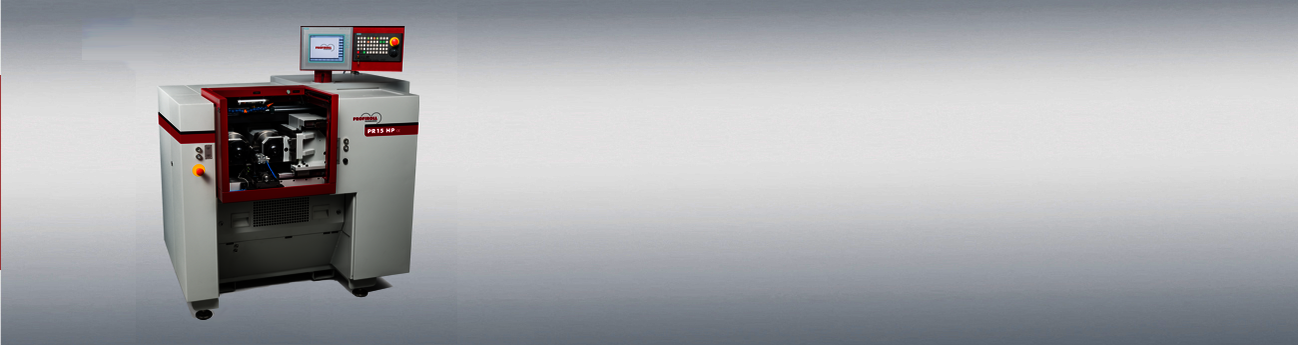

The Innovative - The Next Generation - series of CNC/AC controlled one and two slide machines with the availability of fully programmable rolling parameters, operator assistance and service programs. CNC thread and profile rolling has increased the numbers of profiles which can now be formed.

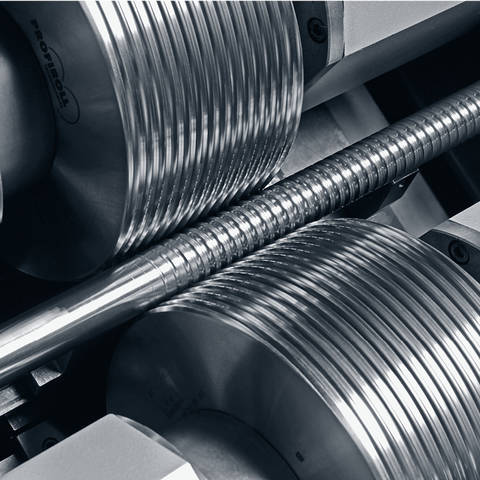

Higher quality of chipless manufactured parts are the decisive argument for changing of the way of thinking in profile rolling technology. With our range of machines we are able to produce highly accurate parts economically even in the smallest of batch runs. Short change-over time, repeatable part programs and computer supported quality control guarantee your leadership over other manufacturers in the technology of precision thread and profile rolling.

The CNC / AC technology with proportional valve technology has been developed into the electromechanical HP drive concept for machines up to 400 kN rolling force. Besides the familiar advantages such as robustness, stiffness and zero backlash, the electromechanical drives have even more positive aspects. The noise level for the operator and maintenance personal is considerably reduced by eliminating the hydraulics power pack. Additionally the energy consumption in series operations is reduced by up to 30 percent for the rolled profiles. Finally the new HP drive concept provides higher thermal machine stability that leads to increased profile precision and size stability rolled parts.

Rolling force: 100kN ... 1000kN (10t ... 100t)

Features:

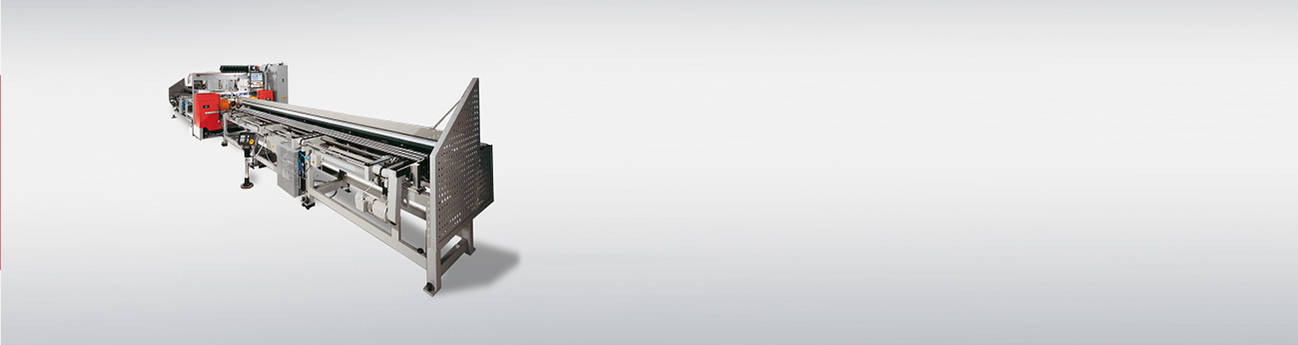

• The machine body is a C-frame with the highest rigidity and the best possible access for the operator and automation.

• The two slide machine guarantees that the part is always in the center position in relation to the dies. No new positioning of loading system is

necessary after change-over to a new part.

• A multiple-axis-CNC/AC control makes the feed oriented process of metal forming possible by the flexible programmable slide movement and spindle speed. This increases the die life while improving the quality of parts.

• Profiroll CNC HMI for easy operating

• The typical parameters of the process are graphically displayed and offer the operator a process picture to analyse and optimise the part program.

• We include the storage of the part program data in the CNC for the shortest change-over time and repeatable rolling process.

• The integrated operator guidance system supports the user in the machine operation.

• Optionally we offer the computer supported quality control by constant monitoring of stroke, force, torque and axial movement complete with

graphic visual displays.

Applications:

• ISO and UN threads

• Whitworth threads

• ACME threads

• Round threads

• Worm profiles

• Knurls RAA and Diamond knurls RGE

• Serrations

• Short splines

• Ballscrews

• unsymmetrical thread

• Burnishing

• Grooves