Spline Rolling

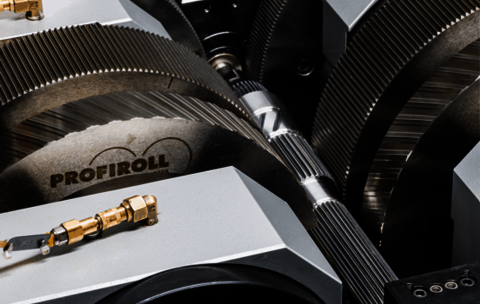

ROLLEX

Profile rolling system ROLLEX for cold rolling of splines is the star in modern production lines because of their productivity, flexibility and achievable quality.

The unique characteristic is the control concept in connection with energy efficient servomechanical drivechain and a reliable rigid design.

- a statically and dynamically very rigid iron cast C-frame

- high accessibility into open work area allows difficult workpiece geometries and rolling of several splines in one tooling layout

- lowest changeover time due to easy handable round dies

- manufacturing of external splines

- flexibility because of possibile profile, finish or thread rolling processes

- Profiroll CNC with hardware base Sinumerik 840D

- data management System

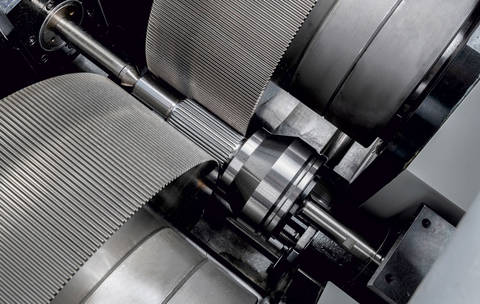

PR 400 HP

The PR 400 HP has been designed purposefully to form workpieces with splines very fast and precisely. The process principle uses incremental spline rolling dies. For accurate and stable rolling results, the machine concept is based on a symmetric, closed power frame, that has been optimized specially with the FEM for up to 400kN rolling force. In cooperation with the strong, backlash-free main drives and the high-precision feed axis, there is hardly any limitation in terms of dynamics and accuracy.

ROLLIN

The ROLLIN is the universal machine for internal splines. Additionally to rolling of internal splines or back tapers there is the possibility to realize finishing processes to calibrate or tighten pre-machined gears.

PRI 120 CNC/AC

The PRI 120 CNC/AC is a newly developed internal spline back-angle rolling machine for the economical manufacturing of back-angle at the tooth flanks of already existing internal spline profiles.

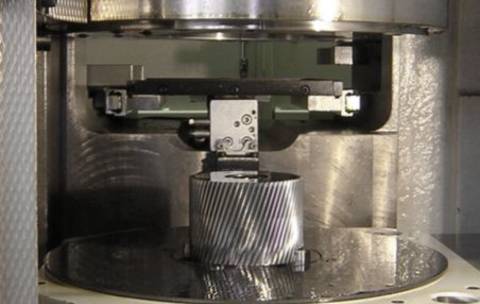

PB 200

The PB 200 is the latest development for forming of annulus gears with internal or external gears in soft condition. The surfaces of gears resulting from machining pre-processes are flattened by this burnishing process and get their final customized characteristics.