PR 400 HP Spline Rolling Machine

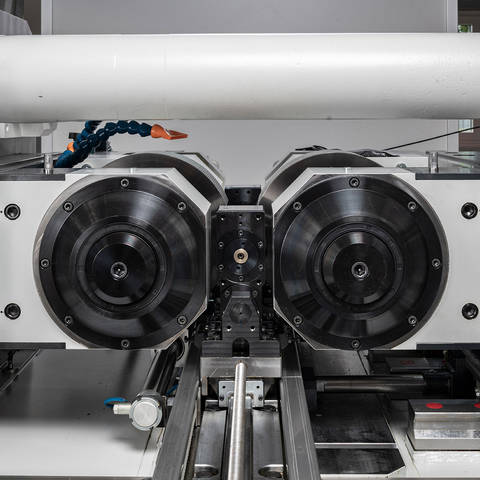

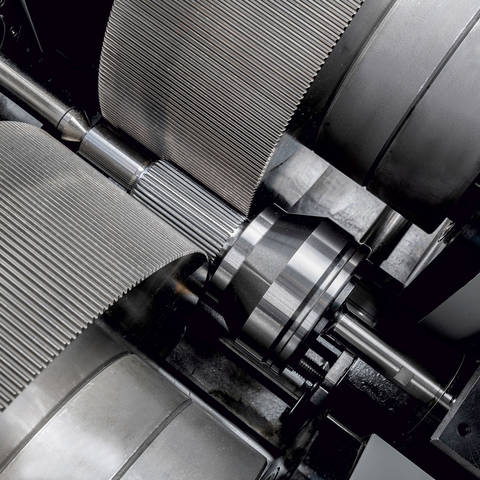

The PR 400 HP was specially developed for the application of incremental spline rolling. Similar to the method with rack dies only the eccentric rolling die design is used to form the splines within one rolling die rotation. There is no longer any need for an active feed axis in the process.

Considering these process kinematics it is clear that one (max. two) profile can be rolled on this machine. But shortest possible cycle time and precise gear tolerance are reward for the user.

The PR 400 HP is controlled by a Siemens 840D sl controller, which impresses with its accessibility and stability. In addition to optimally designed processes, the controller is also supporting the latest universal machine tool interface UMATI.

Features:

- Ideal for workpieces with one single spline (alternatively one additional profile possible)

- HP drive concept with movable slide axis

- Backlash-free main spindle drives

- Profiroll electronic control

- Excellent damping characteristics

- Data management

- Operator guidance