Ring Rolling Process

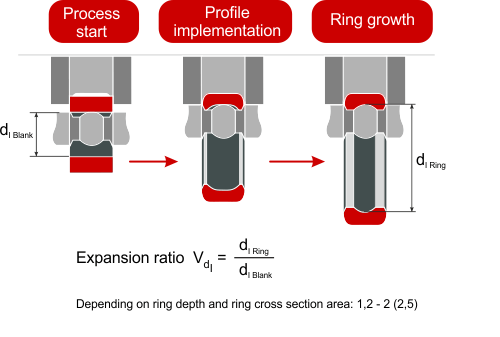

Ring Rolling, developed in the 80s in cooperation with Technical University Dresden, is based on coldforming expansion of ring shaped parts with simultaneous internal and external profiling.

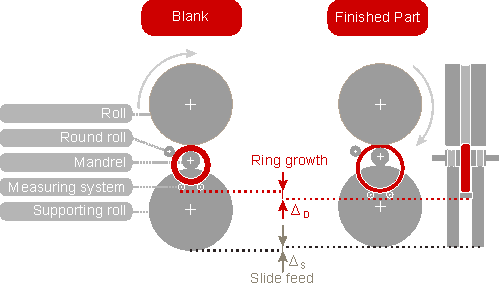

The workpiece will be guided by a profile mandrel. This mandrel is forced by two (2) support rolls which are moving the mandrel against an outer profile roll. There the outer roll coldforms the outer profile of the ring while the mandrel is forming the internal Profile. Additionally there is a steady widening. Rolling process ends when the ring reaches the needed Diameter.

Typical ring rolling process on the URWA 250