Spline Rolling

Typical rollable Dimensions

Typ: DIN 5480; Involute Splines; Serrations

Modul: < 2

Infeed rolling

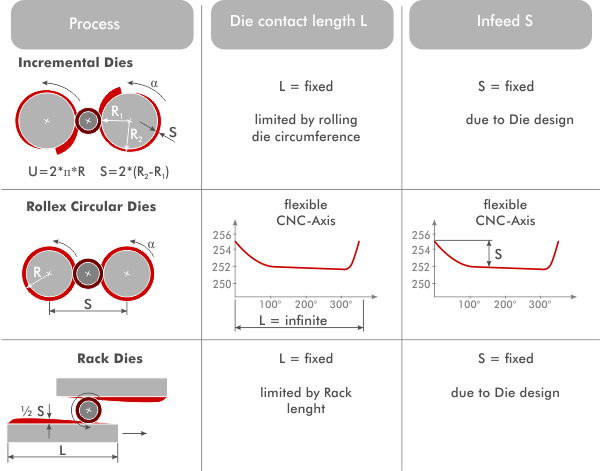

Profiroll process of cold rolling of splines is based on two (2) circular dies which are moved into material with CNC-feed. Using this process an unlimited count of revolutions on the workpiece is possible. Usual Rack process is limited due to length of Rack die itself.

Especially for processes on workpieces with high quality requirements there is no alternative to circular dies technique.

Rollex Spline Rolling

Using PROFIROLL spline rolling technology combined with ROLLEX spline rolling centers allowes you to create more benefits for your company. Our process offers flexible solutions for any spline of gearbox and suspension shafts.

The fully CNC-controlled machine has the capability to handle up to 5 different sets of dies. Each machine setup will developed for the unique customer work-piece. As an result splines can be rolled more stable and controlled without any change of dies or maintenance interruption.

One Advantage of this control results in a throughfeed process:

More and more hollow shafts are used in transmission design. Rolling of splines on such hollow shafts is a real challenge for every force-based concept like coldrolling. Rolling forces up to 100kN and beyond given on small wall thickness - every technician can image that an unwanted deformation could occur.

Profiroll is using here the experience in the field of thread rolling where threads with extended length are rolled with a throughfeed process. One after another the whole profile is rolled with adequate rolling force. This process was adapted for spline rolling. The hollow shaft spline is not longer formed within one infeed step but successively inside a moving coldforming area. Thus the contact area is minimized whereas the high quality spline is formed.

One sample application of the thruforce rolling process are hollow Transmission shafts. Several splines are rolled one after another. Due to hollow shape of shaft sometimes one or more splines have to be rolled in this special process.

Spline Rolling with Profiroll Rollex XL HP

Rolling of aligned splines

A current Topic is manufacturing of several splines that are aligned to each other. For these workpieces it is important to choose the right process: Workpiece clamping and Rolling of splines one after another in several rolling positions or manufacturing of all splines in one single step.

Cold rolling of aligned splines