ROLLEX - The Spline Rolling Machine

The ROLLEX® is more than an innovation offered by Profiroll in the field of Spline Rolling. This flexible machine type enables a rolling of splines onto most different types of shafts. The CNC-control combined with symmetric circular dies allow a manufacturing of splines with highest quality demands. Likewise the ROLLEX® is able to coldform profiles, threads and to perform finishing rolling due to its reliable Profile Rolling process.

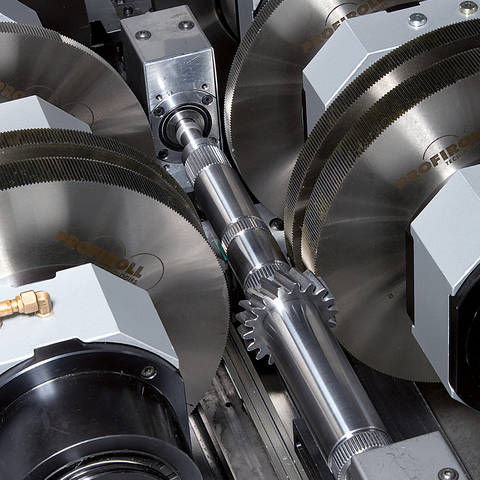

Circular Die Process

- circular dies for kinematic rolling with symmetric geometry

- this correlates to a rolling rack of infinite length

- a workpiece specific calibration phase achieving least tolerances is the result

- lowest changeover times due to compact circular dies

- up to 5 sets of dies mountable in one tooling layout

Process description

Workpieces are to be positioned inside the work area, clamped between centers. The rolling slide infeed starts whereas the Circular Dies on the slides penetrate the workpiece and coldform the requested spline profile. After forming all profiles the workpiece is getting retracted from work area to be replaced by Operator.

Features:

- special drive chain for spline rolling

- controlled workpiece acceleration

- Multiaxes CNC

- 2-Rolling Slides

- Graphical user interface

- Process visualization

- Data management

- User guidance

- machine sizes for different applications

- HP (High Precision) version with servomechanical drives

Why HP-Technique: Saving of electrical energy up to 30% per rolled spline!