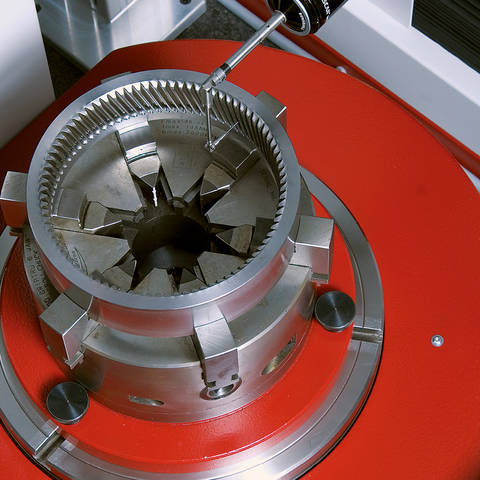

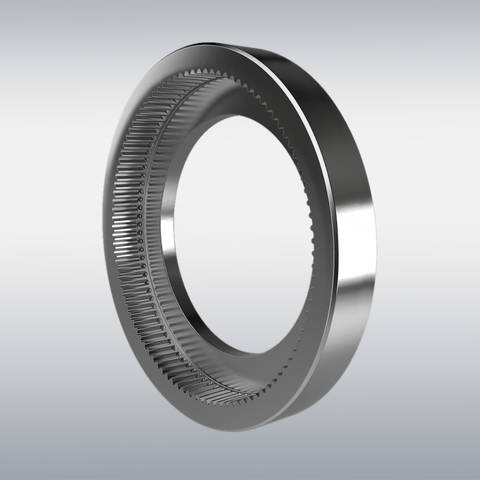

The ROLLIN® is an innovative spline rolling system for internal profiles of high accuracy straight and helical involute splines as well as Finish-Rolling of pre-shaped gears and FBR-D Rolling of Powder Metal on cup- or ring-shaped parts.

The ROLLIN® is essentially different from the conventional Thread and Profile Rolling Machine due to its innovative main drive concept. The main drive is mounted directly on the slide and connected with the main spindle free of deformation. This guarantees the maximum rigidity which is necessary for the spline rolling process. The electronic synchronisation of the workpiece and the rolling die determines decisive the quality of the rolling process. The machine body with its open working area allows the best possible access for the operator. Through the implementation of the most modern propor tional valve and driving technique in connection with the PROFIROLL CNC control a direct influence on the rolling process is possible.

Features of the ROLLIN® are:

- optimized drive chain

- controled, precisly adjustable rolling die acceleration

- Profiroll Multiaxes CNC

- Process visualization

- Data management

- User guidance

The ROLLIN-process is patented by Profiroll.