3-Rolls Thread Rolling Machines

The main characteristic of the unique Profiroll design is the central position of all 3 rolling slides in a pre-loaded double-frame. This ensures highest rigidity. By using the 3-rolls principle the needed force is brought via 3 contact zones into the workpiece material instead of 2. Thus even rolling of hollow parts is possible without compromise in quality or damaging of workpiece.

Features:

- 3-Slide system with symmetric support of dies for centered positioning of workpiece

- Adjustment for your quality requirement

- close double frame that leads to minimized bending

Economical solution

- Electronical Stroke and diameter adjustment

- calculation of pitch deviation

- Proposal of rolling time

Innovative solution

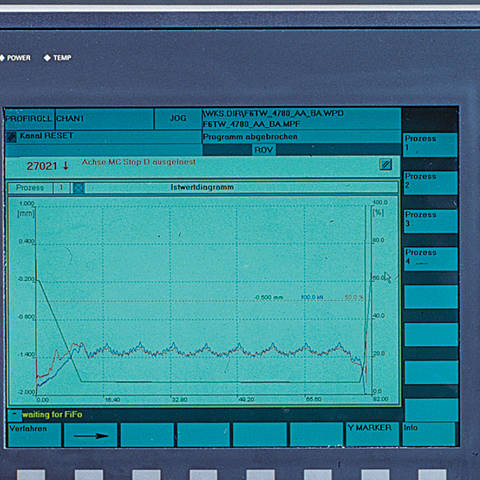

- Multiaxes CNC/AC Control

- Graphical user interface

- Process visualization

- Process data management

- User guidance