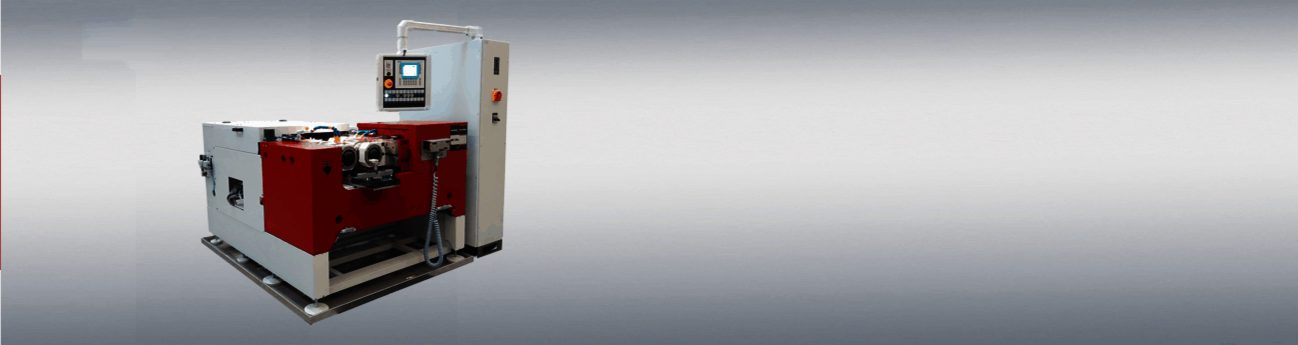

The Economical thread rolling machines

Prepared for automation

The thread rolling machines "The Economical" got their name mostly caused by the ability to work perfect in economical manufacturing solutions and production lines.

The supplied control technology combined with a rigid hydraulic device offer unrestricted connection with automations, short cycle times and only seconds for pitch-finding during die changeover due to usage of PRS (Pitch Reference System PRS®).

Additionally offered technical comfort packages allow every customer to create his personalized rolling system.

Rolling force: 50kN ... 1000kN (5t ... 100t)

Features:

- 1- and 2-Slide versions

- Infeed and Through-feed Rolling

- ability to be automated

- Electronic stroke and diameter adjustment

- Central lubrication

- pre-defined rolling slide graphs

- calculation of profile correction value

- proposal of rolling time

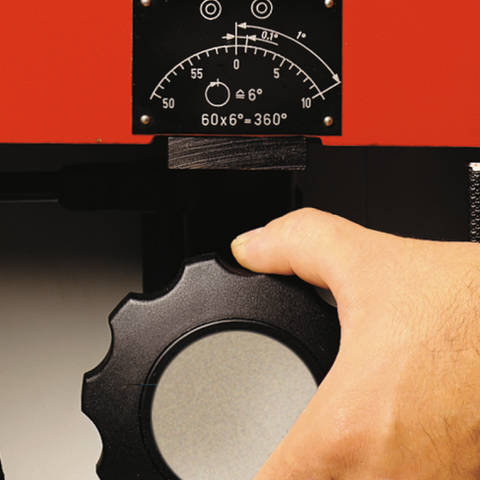

- PRS System for lower changeover times

- best accessibility of work area

- lowest changeover times in general

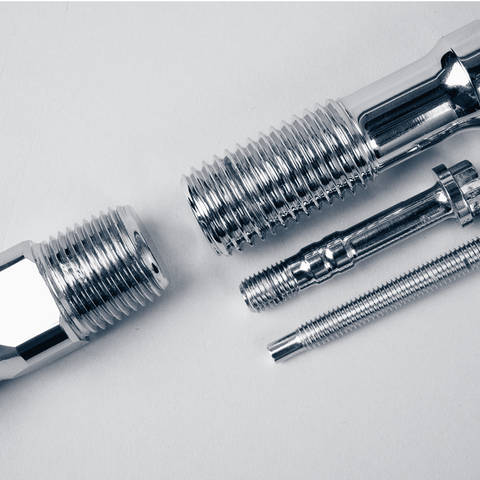

Applications:

- Metric and UN threads

- Whitworth threads

- trapezoidal threads

- Round threads

- Worm profiles

- knurls RAA and RGE

- Splines

- Finish rolling